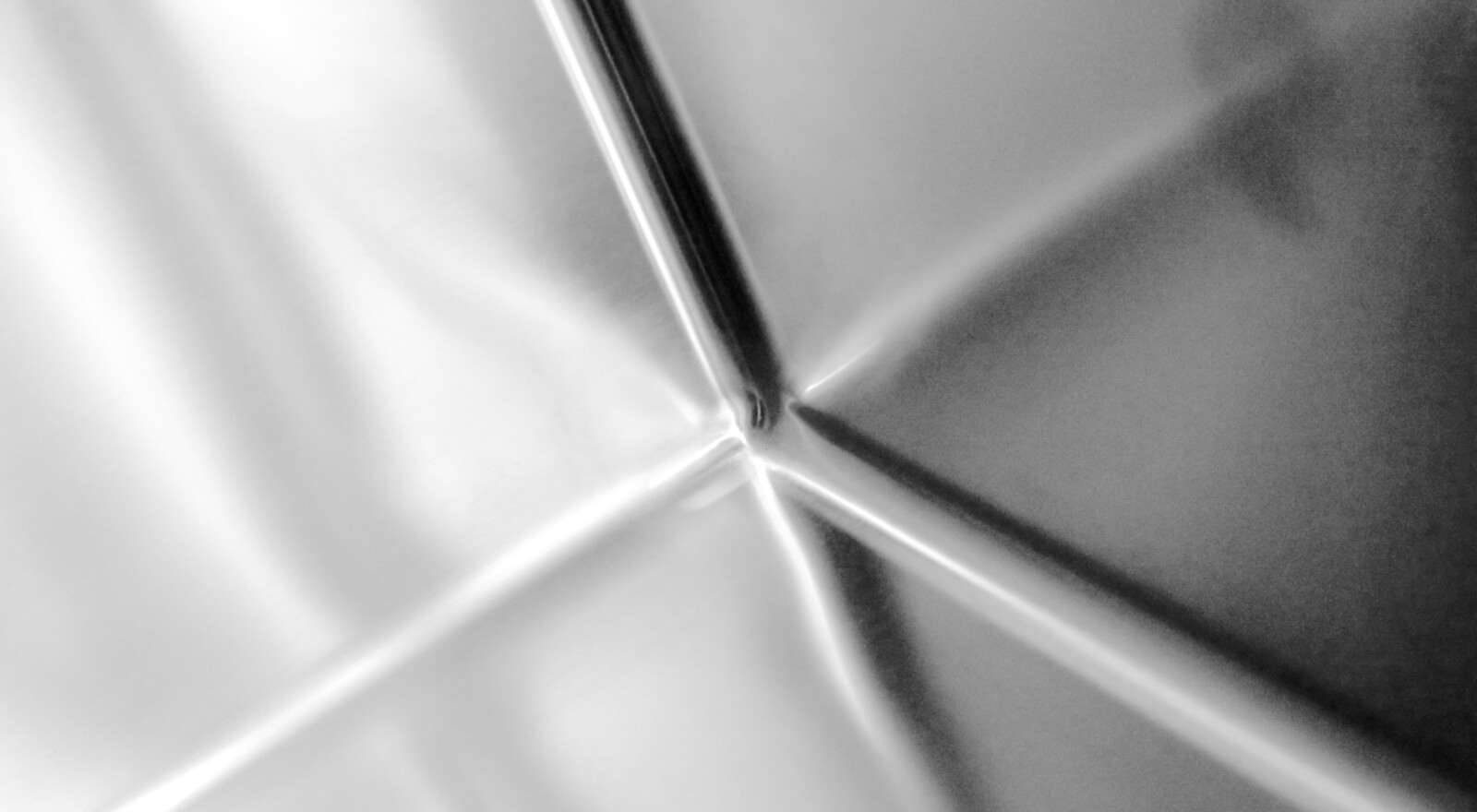

Purity

At each processing stage, a specific level of hygiene

Each food processing phase requires a different construction complexity as well as a specific level of hygiene.

Pursuing what is defined at the conceptual level as “functional separation” of the various processing areas, a targeted design reduces any possible risks of contamination (customer logic) and makes the operating flow more efficient, ensuring maximum professional performance (operator logic).

Thanks to the technical construction measures adopted, Steelnovo is a pioneer in the industrialization of stainless steel furniture, which, beyond complying with DIN 18865-9 (H1, H2, and H3), also sharply satisfy the needs presented by each project.

The company does not merely consider cabinets as the only characterizing element for a higher hygiene level. Even the use of only 18/10 steel (nickel/chrome), the attention we lend while positioning of the furniture (load-bearing plinths as well as cantilever elements), the single-piece structure that minimizes gaps between various components (and increase sturdiness) and lastly the elimination of materials which are naturally subject to deterioration (see LDF or MDF often used to reinforce worktops), must be regarded as a research for structural “purity” in the product that we consider to be of reference on the market.